If you use safety gloves at home or at work, you’ve likely come across the term EN 388 at some point. EN 388 is the European regulation that governs the manufacture of safety gloves designed to protect against mechanical hazards. These numbered markings can be found on nearly all reusable gloves. But what exactly is EN 388, how does it work, and why is it important for you? We’re here to provide all the answers.

What is EN388?

- EN 388 is the European equivalent of ANSI/ISEA 105

- It tests resistance to abrasion, cut, tear, puncture and impact protection gloves

- Level 4 is the maximum rating available for abrasion, tear and puncture resistance

- Cut resistance is measured up to Level 5 or Level F

- Ratings go from low to high, with a lower number (or letter) being a lesser level of protection

- If a glove is marked as “N/A” it means that they haven’t been tested against a given threat

Back to Basics: What Does EN388 Mean?

EN 388 is a certification for work gloves that pass a series of mechanical hazard tests. It evaluates performance across five tests, providing a final score to help users choose the right gloves for their specific risks.

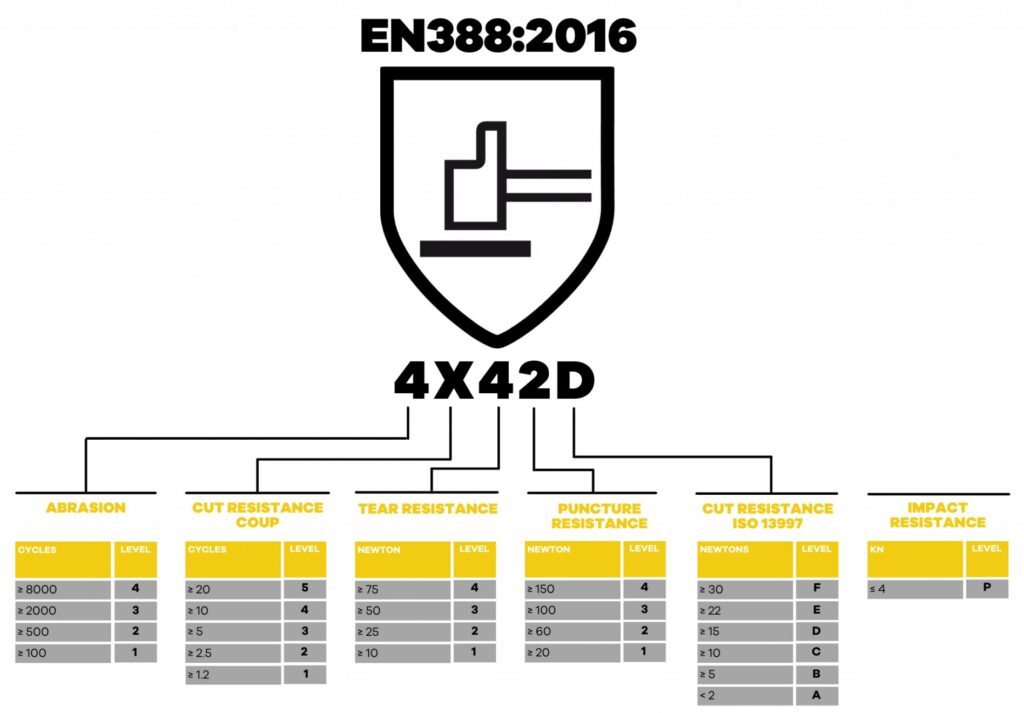

How Do I Read EN388 Markings?

| Abrasion Find Out More | Cut Resistance Find Out More | Tear Resistance Find Out More | Puncture Resistance Find Out More | Cut Resistance ISO 13997 Find Out More | Impact Resistance Find Out More |

The numbers above indicate the scores assigned to your gloves for each tested hazard. You can identify a glove rated EN388 by looking for the corresponding symbol on the back of the gloves, on the packaging, or in the conformity statement.

Abrasion

- The abrasion resistance test measures how well a glove can withstand wear and tear.

- In this test, a glove is placed beneath a moving blade, and the number of cycles it endures before getting damaged is recorded.

- The glove is rated on a scale from 0 to 4, with higher numbers indicating better durability based on the number of cycles before damage occurs.

| Resistance Level | Abrasion Cycles |

|---|---|

| Level 1 | Minimum of 100 Cycles |

| Level 2 | Minimum of 500 Cycles |

| Level 3 | Minimum of 2000 Cycles |

| Level 4 | Minimum of 8000 Cycles |

In simple terms, gloves with high abrasion resistance are more durable. These gloves are ideal for handling rough materials without falling apart.

Cut Resistance

- The 2003 version of the EN 388 cut-resistance test involves a circular blade being lowered onto a piece of the glove’s fabric.

- A downward pressure of five newtons is applied to the fabric until the blade cuts through it.

- This action stops the test and activates an electrical sensor located beneath the fabric

| Cut Resistance Rating | Number of Cuts Withstood |

|---|---|

| Level 1 | 1.2 Cuts |

| Level 2 | 2.5 Cuts |

| Level 3 | 5 Cuts |

| Level 4 | 10 Cuts |

| Level 5 | 20 Cuts |

In simple terms, cut-resistant gloves are beneficial for individuals who work with knives, blades, or sharp edges. The higher the cut resistance level, the better your hands are protected from cuts and lacerations.

Tear Resistance

- Tear resistance is measured by clamping a glove between two separate vices that are gradually pulled apart.

- The jaws of these vices move apart at a constant speed, and the force required to tear or rip the fabric’s fibres is measured. This measurement is then assigned one of four different level ratings.

| Tear Resisitance | Tear Force (Newtons) |

|---|---|

| Level 1 | 10N |

| Level 2 | 25N |

| Level 3 | 50N |

| Level 4 | 75N |

In simple terms, tear resistance is an important factor to consider when assessing the durability of work gloves, just like abrasion resistance. Gloves with higher tear resistance are less likely to get snagged or ripped during use, which can save you the hassle and expense of having to replace them frequently.

Puncture Resistance

- The puncture resistance of gloves is measured by applying a standard rounded stylus to the palm fabric of the gloves.

- The stylus is pushed 50 mm into the glove at a constant speed of 100 mm per minute using a specially designed compression test machine.

- The maximum force required to puncture the glove before breakage is recorded, which determines one of four resistance levels.

| Resistance Level | Puncture Force (Newtons) |

|---|---|

| Level 1 | 20N |

| Level 2 | 60N |

| Level 3 | 100N |

| Level 4 | 150N |

Puncture-resistant gloves are less likely to tear or develop holes. However, higher levels of puncture resistance do not protect against very sharp objects, such as needles.

Cut Resistance ISO 13997

The second cut-resistance test differs from the first. Reformulated in 2016, this test was introduced to address the issue of “blade dulling.” In the original test, the circular blade would become blunt over time, making it too easy for gloves to achieve a high resistance rating.

The 2016 version uses a single, straight blade that is repeatedly drawn across the glove until it cuts through. This new testing method eliminates the problem of blade blunting that affected the original 2003 version.

| Cut Resistance ISO 13397 | Force Tolerated (Newtons) |

|---|---|

| Level A | Up to 2N |

| Level B | Up to 5N |

| Level C | Up to 10N |

| Level D | Up to 15N |

| Level E | Up to 22N |

| Level F | Up to 30N |

In simple terms, the ISO Cut is a new method for measuring cut resistance that more closely aligns with the types of threats you might encounter at work. Unlike the old cut resistance ratings, which ranged from 1 to 5, the new ISO Cut system includes six levels.

Specifically, Level C is approximately equivalent to the old Level 5, and the higher levels provide a more straightforward way to identify gloves with exceptional cut resistance.

Impact

Impact resistance is minimally different. The glove will either achieve a Level P (standing for “Pass”) or it will not provide a result, meaning that most gloves won’t display results for impact resistance.

Impact-resistant gloves are ideal for those who often hit the back of their hands while working. They come with shock-absorbing pads that lessen the impact felt by your hand.

Frequently Asked Questions

What Is the Difference Between the Two Cut Tests?

The main difference between the two tests is that the circular blade test uses a rotating blade, while the ISO cut test employs a straight, non-rotating blade that is pressed down onto the glove. The ISO cut test is the newer and more stringent standard because the blade used in the circular blade test tends to become blunt during testing.

Are Gloves tested for everything?

Gloves are typically tested for several factors, including abrasion, puncture, tear resistance, and one type of cut resistance. However, many newer gloves are not evaluated using the traditional circular cut test, while older gloves may not have been retested using the more recent straight cut test. Additionally, only a small percentage of gloves undergo impact resistance testing.

What If a Glove Fails a Test?

If a glove fails a test it will achieve a Level 0.

Are All Reusable Gloves Tested to EN 388?

Not all reusable Gloves will be tested to EN 388. For example, some Gardening, Rigger, Cotton and some low risk Handling Gloves might not have been tested to this standard. This doesn’t mean that they are useless, but rather that they are better suited to low-risk work