A simple guide to buying a Portable Router

There two main types of router, the plunge router and a fixed base router. The plunge router allows mortise slots to be routed quickly and easily as the motor head can plunge in relation to the base. A fixed base router uses a rotating body to alter the depth, which can make routing of a mortise slots quite difficult. Another factor to consider is that on fixed base routers the cutter does not quickly retract into the base for safety. Fixed base routers are only sold in North America. There are few combination routers that have both a plunge base and fixed base.

The user needs to decide what the plunge router will mainly be used for, as this will dictate whether a ¼ inch or ½ inch collet router is required. ¼ inch routers are smaller, lighter and run at higher speeds, there are also light duty and medium duty models available. ½ inch routers will be heavier and more powerful and can be used for a variety of heavier duty applications.

A variable speed ½ inch router is best suited for router table use as it allows larger panel cutters to be used. A heavy-duty router designed for router table use is the Trend 2000 watt T11E router that has above and below the table fine height adjustment, which makes cutter height adjustment very easy. The router also has fittings for quick fitting and release from a router table such as the Trend Professional Router Table or CraftPro router table

A ¼ inch medium duty plunge router is ideal when used with a door-hanging jig, as it is lighter, an example is the Trend 1000 watt T4EK router.

If a router is being used to rout kitchen worktop joints with a worktop jig the machine must have a 1/2 inch collet capacity, such as the 2000 watt Trend T10E. The guide bush to cutter accuracy must also be considered when a perfect joint is required; if the guide bush is not concentric the resulting cut will be offset.

If a router is to be used for carving, it is worth considering using a router that has a removable base such as the Trend 850 watt T4E router.

If router is to be used on site it is also worth considering if the tool is supplied in a sturdy kit box/storage case, as this will protect the tool, and keep the standard accessories together.

Routers are rated on their input wattage, which ranges from 400 watts for a basic DIY router to around 3000 watts for a heavy-duty industrial machine. The maximum speed at which these machines operate varies between 10,000 and 32,000 rpm. The high speed is an important factor in routing, as it is this that is relied upon to produce the quality and precision of the finish, rather than out and out power, as would be the case with stationary machines with large heavy motors. Because of this you will find that many of the higher-powered routers actually run at lower speeds, the lower powered models needing this high-speed factor to compensate for the lack of power. It is also worth remembering that the power output from any power tool isn’t the same as its power input. The output often being as little as 55 to 65 per cent of the input.

It is also worth noting that the router voltage will need to be confirmed, routers can be supplied in 240-volt and 115-volt. 115-volt is used for building site use. 115-volt machines are plugged into a generator or transformer, the lower voltage offer better safety to the user in case of contact with live parts.

All routers used must meet the current European standards for power tool safety.

To get the best from a router it is well worth knowing a little of what goes on inside and of course what the controls are for, so here is a simple guide to the inside of a router.

The standard and quality of manufacture, and price paid, will be reflected in the efficiency with which the router can utilise the input power, and how much is wasted in transmission. The price will also reflect the quality and precision of standard accessories such as side fences and fine height adjusters supplied with the tool as well as the tool itself.

For the beginner wishing to attempt a range of household projects, such as simple furniture construction, a router of less than 1000 watts will limit the type of work you can undertake and the size of cutters you can use.

A lower wattage router will also slow you down because the amount of material you can actually remove during each cut will be limited, as will the speed you can feed the router into the material.

Ventilation intake slots explanation.

Air is pulled in here to cool the motor and bearings. These slots (or grilles) should be kept clear while the router is running to maintain a flow of air.

Always ensure that chips and other waste are kept away to prevent them being sucked into the router.

Moulded plastic top vent

This guards and protects the top bearing and armature commutator but, if separate from the body moulding, can be occasionally removed to clear dust and inspect or change the carbon brushes.

Armature

This is the rotating coil of the electric motor, which is wound on the motor spindle. The spindle is machined to take the collet and nut to hold the cutter. Some routers have a deeper hole in the armature, which allows longer cutters to be inserted.

Field Coil

This is the stationary electric coil that creates the opposing magnetic field to cause the armature to rotate.

Bearings

The spindle is mounted in a pair of bearing races to help it run smoothly. They are carefully aligned and firmly seated in the motor housing. Sealed bearings are packed with grease and (if the tool is not abused) should require no maintenance. Although they should have a life expectancy of at least 100 hours running time. It is worth checking them regularly for play and, if necessary, replacing them.

Plunge columns

These allow the router to plunge accurately down to enter the cutter into the work at 90 degrees. Return springs lift the motor housing to ensure that the cutter is retracted from the cut when the operation is complete. These columns should be kept clean and lightly oiled to ensure a smooth plunge action. Routers with a longer plunge, such as Trend’s T10 or T11, will allow the user to achieve greater depth (up to 80 mm), particularly useful when routing deep mortises.

Plunge lock knob or lever

This is used to lock the router body at the required height on the plunge columns, to set the depth of the exposed cutter (i.e. the depth of cut) beneath the base plate. The Trend T5E plunge is controlled by twisting one of the handles, and makes plunge lock control very easy. Other routers including the Trend T4E, T10E & T11E use a plunge lever to release plunge.

Adjustable depth stop

Operated either manually or by a ratchet/knob, this allows the plunge depth to be pre-set to the required depth of cut. A good design of adjustable depth stop is essential for larger routers being used for jobs such as routing worktops and lock recesses, where the depth will need to be adjusted several times to complete the cut. A rotating turret stop with adjustable height studs is also useful when cutter depth changes are required.

Depth scale

Generally graduated in millimetres, this allows fine adjustment of the cutting depth without having to measure the exposed cutter length.

Side handles

These are used to control the motion of the router, and aid with plunging. Trend routers are designed with the customer in mind and all have ergonomic, and easy to grip handles for ease of use.

Switch

The switch is usually found near (or incorporated into) one of the handles. Some models for example the Trend T5EK/MK2 have what is called a safety or “dead mans” switch. This is a switch which has to be held on during the routing operation, and once released the motor is switched off.

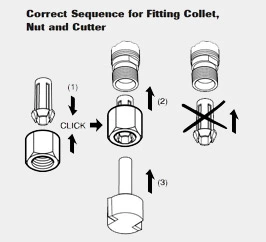

Collet and collet nut

The collet is designed to centre the cutter in line with the axis of the motor spindle. If the cutter is out of line, it will cut erratically and vibrate the machine, potentially causing damage to cutter and work piece. The collet lock nut is tightened to squeeze the collet and grip the cutter shank. Trend use one-piece multi-slit collets in most of their routers, which provide maximum grip on the shank surface.

Spindle lock

On early routers the collet lock nut was tightened using two spanners, later models have a spindle lock eliminating the need for one of the spanners and making it easier to tighten the nut in the confined space between the plunge columns. It is also advisable to use a good quality forged spanner when tightening the collet nut rather than softer pressed steel spanners, which can deform.

Side fence

All Trend routers are supplied with a side-fence, which is used to guide the router parallel to the edge of the work. Some less expensive routers are not supplied with a side fence, and do not have universal fittings to allow one to be attached. Trend routers use a common rod centre, allowing side fences to be fitted to other machines with the same rod centres. The Trend T4E and T5E use 8mm rods with 84mm centres. The Trend T5E, T10 and T11 routers also have a micro adjuster incorporated into the fence to allow for fine adjustment when positioning the cutter on the work.

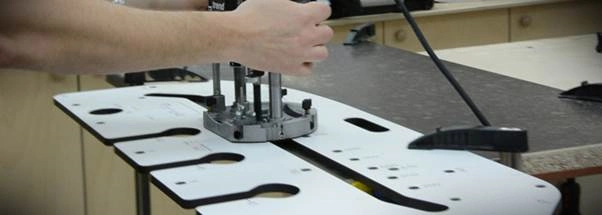

Threaded mounting points

A number of routers have the facility to bolt on sub-bases, however these may need to be specially drilled. These fixing points can also be used for mounting the router onto jigs and router tables. All Trend routers use the TBC (Trend Base Configuration), which provide a common format fixing point for routing jigs and tables. The TBC standard logo appears on the applicable Trend product packaging. By choosing a router with a TBC base there is no issue with compatibility with the wide selection of Trend routing jigs and accessories.

Rotating turret stops

Most routers have a turret stop of some design. Be it a standard 3-stage turret stop, or multi-staged version, it allows the depth of cut to be quickly re-set to facilitate cutting in steps. This is to avoid overloading the router or burning the cutter. With low powered routers the cutting depth on each pass should be no more than 3 to 6mm and must never exceed the cutter diameter. Using the more powerful routers, a deeper cut can be made on each pass but again; shallow passes are recommended to produce the best results.

Router base and slider

The underside of the base plate of most routers is faced with a plastic material to allow the router to glide easily on the work without marking its surface. This is generally fixed with adhesive, but some are fixed with screws only, and can be replaced when worn. The slider plates are made from laminate or from moulded plastic. Laminate sliders are preferred as they have a flatter tolerance and harder wearing surface. Some router base plates also have centre line mark cast into the edge, which allows the router to be centred easily for grooving or plunge drilling. It is advisable to select a router that has at least one flat on the base so that it can easily be guided by a batten or clamp guide.

Side fence rods

The side fence body slides on the rods to position the router from the edge guide. The rods are locked in position with the thumbscrews. Trend routers use either 8mm or 10mm diameter rods for the side fences. Extra long 500mm long rods are available in both sizes, to increase side fence reach.

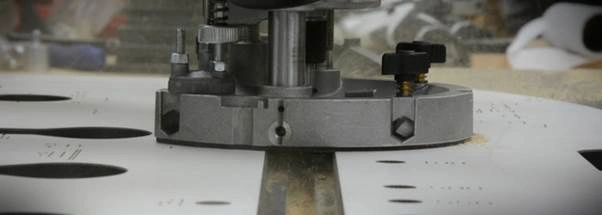

Guide bush mounting points

Template guide bushes can be fitted to most routers and are used to guide the cutter when using a template or jig. The Trend T10 and T11 routers have adjustable centring plates, which enable the guide bush to be centred on the router spindle using a line-up pin that is fitted into the collet. This line up pin is then used to centre the 30mm guide bush. Trend use the Euro style of guide bush and have the largest selection of guide bushes available with sizes ranging from 7.74mm to 40mm in diameter. Euro style guide bushes will fit a wide range of different makes of router directly that have a 60mm recess. Alternatively a circular sub-base Trend ref UNIBASE can be fitted to a router to accept the guide bushes. This sub-base includes a line up bush and pin to ensure guide bush to cutter accuracy. There are even larger guide bushes available for the Trend T11E up to 70mm diameter.

Dust extraction spout

Most routers are supplied with a removable dust spout, which helps deflect the dust and chips away from the operator and to extract them via a vacuum extractor. Some dust spouts are bolted into the router base, whereas others such as the Trend T5E have a clip-in spout for ease of removal. It is advisable to select routers with common outlet dust spout sizes for convenience.

Fine height adjustment

A fine height adjuster accessory is one of the most useful accessories for a router. The adjuster for the T5 allows for fine cutter height adjustment when used on a dovetail jig or a router table. The fine height adjuster is fitted to the tallest stud on the turret stop while the router is plunged down. Some routers, such as the T10E, have what is called an adjustable return stop and nut fitted onto a stud that is connected to the router base plate. The fine height adjuster is sometimes fitted in place of the nut on the stud. The Trend T11E router is supplied with a ‘Quick Raiser’ fine height adjuster so that when the router is fitted in a router table, the router height can be adjusted from above or below the table surface. This makes table routing much easier. One revolution of the handle equals 1.5mm of height adjustment.

Carbon brushes

Two carbon brushes are fitted which run against the commutator under light spring pressure. Excess sparking is usually an indication that the brushes have worn and need replacing. Please note carbon brush motors should only be run 20 minutes in every hour.

Variable speed setting control

This allows the operating speed to be pre-set to accommodate the use of large diameter cutters, which should be used at lower speeds. Higher quality routers are fitted with full wave electronics to maintain a steady and smooth power supply throughout the speed range, monitor the load on the cutter to keep the speed constant and eliminate the harsh kick common to high speed motors on start up (soft start).

Getting started

By using just a small amount of different router cutter profiles you can perform a surprising number of routing operations.

HSS (high speed steel) cutters are commonly used for cutting aluminium, plastics and softwood. TCT (Tungsten Carbide Tipped) cutters are used for cutting softwoods, hardwoods, MDF, plywood, chipboard and abrasive plastics such as solid laminate and solid surfaces.

So whether you’re a master carpenter, tradesman, keen woodworker or DIY’er there is a router and cutters available to help you finish your work or projects quicker, easier and to a professional standard.

If you found this article helpful please remember to SHARE it with your friends and colleagues by clicking the social media icons below.